Pilot Plant for external sludge handling (Work package 3)

Approximately 50% of municipal residents are connected to the municipal pipeline network system in Höör and Hörby municipalities (Sweden). Other properties have their own sewage disposal plants consisting of sludge separator or closed tank. These plants are emptied by the cleaning company once a year and the sludge (external sludge) goes to the municipal treatment plant for the furher treatment. During recent years the municipality has discovered that there are high metal concentrations in the external sludge delivered to the wastewater treatment plants in Höör and Hörby. As a result, the sludge produced from the wastewater treatment plants is deteriorating. Therefore in the long term perspective can be difficul to find a final sludge disposal.

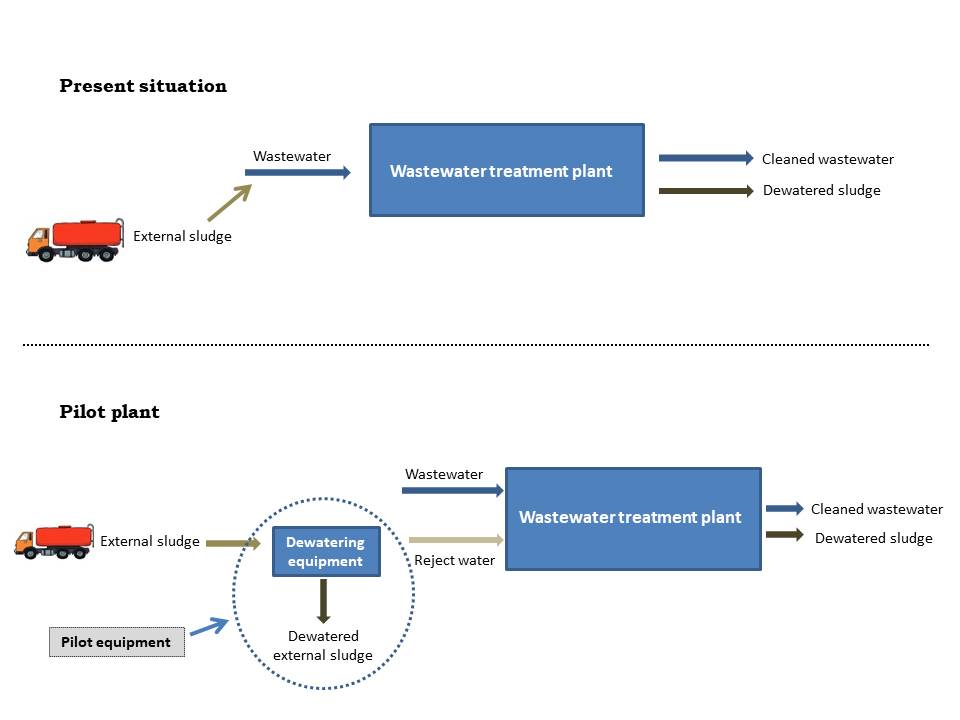

Studies have shown that metals remains in the sludge in the dewatering of external sludge and the reject water can be treated in the treatment plant without deteriorating the sludge from the wastewater treatment plant.

In the pilot plant, the external sludge is dewatered in a separate plant and only the reject water is discharged to the treatment plant. The dewatered external sludge is handled separately and is not treated with wastewater in the treatment plant. This will cause the sludge produced at the treatment plant to get a better quality with low metal content because it is not polluted by the external sludge.

The plant was operating for one month. When the results were compiled at the end of the trial period it indeed could be seen that it was possible to separate the heavy metals, most ended up in the sludge and not in the supernatant. There are some uncertainties, but in general it can be said that about 80-90 % of the metals were found in the dewatered sludge. This then would imply that metal contents in the outgoing sludge from the main treatment plant would be reduced by 5-15 % if separation is applied in the overall process.

Another conclusion from the trial period is that the external sludge was easy to dewater. The levels of dry matter varied between 28 to 41 % without any real optimization of the equipment at the wastewater treatment plant.

Now, Mittskåne Water will take these results into consideration when planning for a new inlet to the main treatment plant in Höör. There seems to be clear benefits in the long term by installing a permanent process step where external sludge is treated separately.

Photo gallery (Pilot Plant on site):

Lider projektu

Zachodniopomorski Uniwersytet Technologiczny w Szczecinie

Wydział elektryczny

Zachodniopomorski Uniwersytet Technologiczny w Szczecinie

Adres: ul. Sikorskiego 37

70-313 Szczecin

Telefon: +487 (258) 60 950

E-mail: marcin.holub@zut.edu.pl

Kontakt: asystent profesora dr hab. inż. Marcin Holub

Email's

Lider projektu: marcin.holub@zut.edu.pl

Partner 2: toj@beof.dk

Partner 3: olga.anne@ku.lt

Partner 4: elin.olsson@mittskanevatten.se

Partner 5: d.kozak@gwik.pl

Phone's

Lider projektu: +487 (258) 60 950

Partner 2: +455 (690) 0000

Partner 3: +370 (616) 15335

Partner 4: 0413-286 28

Partner 5: +503 197 780